Consulte las especificaciones para obtener detalles del producto.

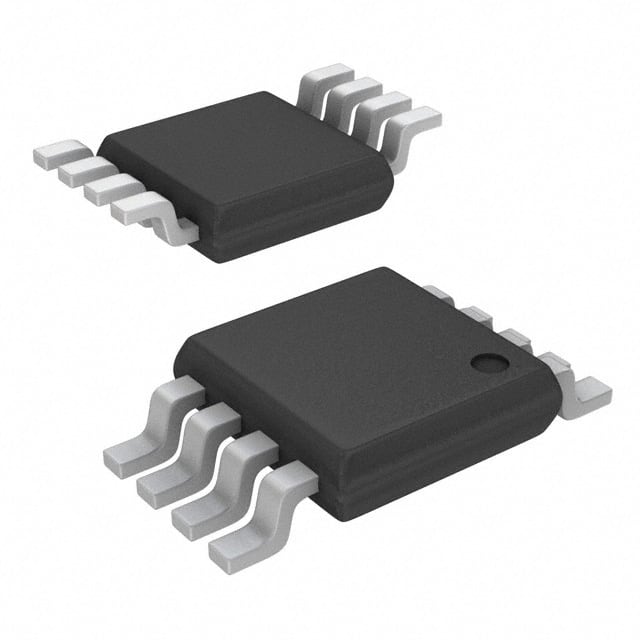

AS1973

Product Overview

- Category: Integrated Circuit (IC)

- Use: Power Management

- Characteristics:

- High efficiency voltage regulator

- Low power consumption

- Small form factor

- Wide input voltage range

- Package: SOP-8 (Small Outline Package)

- Essence: Voltage Regulator IC

- Packaging/Quantity: Tape and Reel, 2500 units per reel

Specifications

- Input Voltage Range: 4.5V to 24V

- Output Voltage Range: 1.2V to 18V

- Maximum Output Current: 1.5A

- Quiescent Current: 50µA

- Dropout Voltage: 200mV

- Operating Temperature Range: -40°C to +85°C

Detailed Pin Configuration

The AS1973 IC has a SOP-8 package with the following pin configuration:

- VIN: Input Voltage

- GND: Ground

- EN: Enable Pin

- FB: Feedback Pin

- VOUT: Output Voltage

- NC: No Connection

- NC: No Connection

- VREF: Reference Voltage

Functional Features

- High efficiency conversion of input voltage to output voltage

- Low power consumption in standby mode

- Overcurrent protection

- Thermal shutdown protection

- Short-circuit protection

Advantages and Disadvantages

Advantages: - High efficiency operation - Wide input voltage range - Small form factor - Overcurrent and short-circuit protection

Disadvantages: - Limited maximum output current (1.5A)

Working Principles

The AS1973 is a voltage regulator IC that converts an input voltage within the range of 4.5V to 24V to a regulated output voltage between 1.2V and 18V. It achieves high efficiency by utilizing a switching regulator topology. The IC operates in continuous mode, adjusting the duty cycle of the internal switch to maintain the desired output voltage. It also incorporates various protection features to ensure safe operation.

Detailed Application Field Plans

The AS1973 is commonly used in various applications that require efficient power management. Some of the typical application fields include:

- Battery-powered devices

- Portable electronic devices

- Industrial automation systems

- Automotive electronics

- LED lighting systems

Detailed and Complete Alternative Models

- AS1974: Similar specifications with enhanced overcurrent protection

- AS1975: Higher maximum output current (2A) with similar characteristics

- AS1976: Adjustable output voltage range with similar package and features

These alternative models provide flexibility in choosing the right voltage regulator IC based on specific requirements.

In conclusion, the AS1973 is a highly efficient voltage regulator IC designed for power management applications. Its small form factor, wide input voltage range, and various protection features make it suitable for a wide range of electronic devices. With its excellent performance and reliability, the AS1973 offers an effective solution for efficient power conversion.

Enumere 10 preguntas y respuestas comunes relacionadas con la aplicación de AS1973 en soluciones técnicas

Sure! Here are 10 common questions and answers related to the application of AS1973 in technical solutions:

Q: What is AS1973? A: AS1973 is a technical standard that provides guidelines for the design, installation, and maintenance of electrical equipment in hazardous areas.

Q: What are hazardous areas? A: Hazardous areas are locations where flammable gases, vapors, or combustible dusts are present, which can potentially cause explosions or fires.

Q: How does AS1973 help in technical solutions? A: AS1973 helps ensure the safe operation of electrical equipment in hazardous areas by providing specific requirements and recommendations for their design, installation, and maintenance.

Q: What types of equipment does AS1973 cover? A: AS1973 covers various types of electrical equipment, including lighting fixtures, switches, control panels, motors, and communication devices used in hazardous areas.

Q: Are there different zones defined in AS1973? A: Yes, AS1973 defines different zones based on the likelihood and duration of the presence of flammable substances. These zones help determine the appropriate equipment and protection methods required.

Q: What are some key considerations when designing electrical systems in hazardous areas? A: Key considerations include selecting suitable equipment with appropriate explosion protection methods, ensuring proper grounding and bonding, and implementing effective maintenance procedures.

Q: Can I use non-certified equipment in hazardous areas? A: No, AS1973 requires the use of certified equipment specifically designed and tested for use in hazardous areas to ensure they meet the necessary safety standards.

Q: How often should electrical equipment in hazardous areas be inspected? A: AS1973 recommends regular inspections and maintenance at specified intervals to ensure the ongoing safety and reliability of the equipment.

Q: Are there specific requirements for labeling equipment in hazardous areas? A: Yes, AS1973 specifies that all electrical equipment in hazardous areas should be clearly labeled with appropriate markings indicating their suitability for use in those specific zones.

Q: Who is responsible for ensuring compliance with AS1973? A: Ultimately, it is the responsibility of the owner or operator of the facility to ensure compliance with AS1973. However, consulting with qualified electrical engineers and professionals is highly recommended to ensure proper implementation.

Please note that these questions and answers are general in nature and may vary depending on specific circumstances and local regulations.