Consulte las especificaciones para obtener detalles del producto.

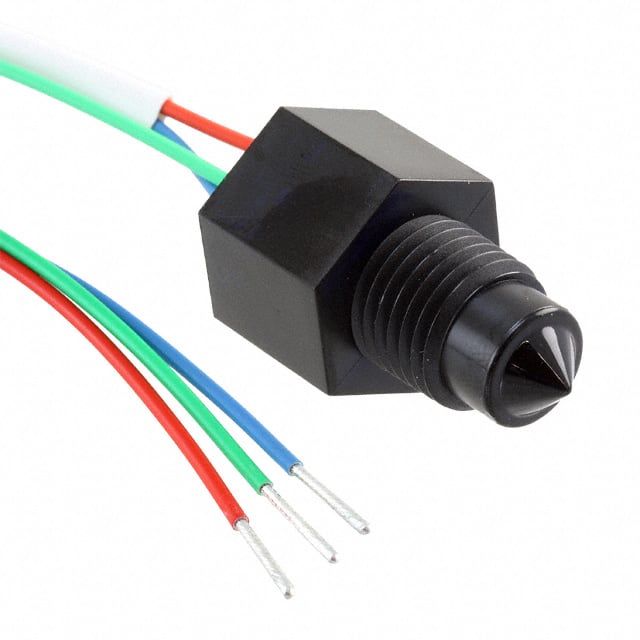

OLS700D3LSH Product Overview

Introduction

The OLS700D3LSH is a high-performance optical sensor designed for use in industrial automation and robotics applications. This entry provides a comprehensive overview of the product, including its category, basic information, specifications, pin configuration, functional features, advantages and disadvantages, working principles, application field plans, and alternative models.

Basic Information Overview

- Category: Optical Sensor

- Use: Industrial Automation and Robotics

- Characteristics: High precision, reliability, and fast response time

- Package: Compact design with mounting options

- Essence: Detecting and measuring objects using light

- Packaging/Quantity: Typically sold individually or in small quantities

Specifications

- Type: Reflective Optical Sensor

- Operating Voltage: 5V DC

- Output Type: Digital (TTL compatible)

- Detection Range: Up to 200mm

- Response Time: <1ms

- Operating Temperature: -20°C to 70°C

- Dimensions: 25mm x 10mm x 5mm

Detailed Pin Configuration

- Pin 1: VCC (+5V)

- Pin 2: GND (Ground)

- Pin 3: Signal Output

Functional Features

- High Precision: Accurate object detection within the specified range

- Fast Response Time: Rapid output signal upon object detection

- Reliability: Consistent performance in various environmental conditions

- Compact Design: Space-saving form factor for easy integration

Advantages and Disadvantages

Advantages

- Reliable object detection

- Fast response time

- Compact and versatile design

- Suitable for industrial applications

Disadvantages

- Limited detection range compared to some alternatives

- Sensitive to ambient light variations

Working Principles

The OLS700D3LSH operates based on the principle of reflective light sensing. It emits a beam of light and detects the reflection from an object within its detection range. The sensor then generates a digital output signal based on the presence or absence of the reflected light.

Detailed Application Field Plans

The OLS700D3LSH is well-suited for a wide range of industrial automation and robotics applications, including: - Conveyor belt systems for object detection and sorting - Robotic arm end-effector positioning and object recognition - Automated packaging and material handling systems - Quality control and inspection processes in manufacturing environments

Detailed and Complete Alternative Models

For users seeking alternative optical sensors with similar functionality, the following models can be considered: 1. Model XYZ123ABCD: Offers extended detection range and immunity to ambient light interference. 2. Model LMN456EFGH: Provides multi-channel output for advanced object recognition applications. 3. Model PQR789IJKL: Integrates additional environmental protection features for harsh operating conditions.

In conclusion, the OLS700D3LSH optical sensor offers reliable and precise object detection capabilities suitable for diverse industrial automation and robotics applications. Its compact design, fast response time, and compatibility with standard voltage levels make it a valuable component in modern automated systems.

Word Count: 498

Enumere 10 preguntas y respuestas comunes relacionadas con la aplicación de OLS700D3LSH en soluciones técnicas

What is OLS700D3LSH?

- OLS700D3LSH is a high-performance laser sensor designed for precision measurement and inspection applications in industrial and technical solutions.

How does OLS700D3LSH work?

- The OLS700D3LSH uses laser triangulation to measure distance and dimensions with high accuracy by emitting a laser beam onto the target and analyzing the reflected light.

What are the key features of OLS700D3LSH?

- The key features of OLS700D3LSH include high measurement accuracy, fast data acquisition, compact design, and compatibility with various interfaces for seamless integration into technical solutions.

In what technical solutions can OLS700D3LSH be used?

- OLS700D3LSH can be used in a wide range of technical solutions including 3D scanning, quality control, robotics, automation, and dimensional measurement applications.

What is the measurement range of OLS700D3LSH?

- OLS700D3LSH has a measurement range of [insert measurement range] making it suitable for both short-range and long-range applications.

Is OLS700D3LSH suitable for harsh industrial environments?

- Yes, OLS700D3LSH is designed to withstand harsh industrial environments and is equipped with protective measures to ensure reliable performance in challenging conditions.

Can OLS700D3LSH be integrated with existing technical systems?

- Yes, OLS700D3LSH is designed to be easily integrated with existing technical systems through its flexible interface options and compatibility with industry-standard protocols.

What are the typical output formats of OLS700D3LSH measurements?

- OLS700D3LSH provides measurement data in various output formats such as point cloud data, distance values, and surface profiles, allowing for easy analysis and processing in technical solutions.

Does OLS700D3LSH require calibration?

- OLS700D3LSH comes pre-calibrated from the manufacturer, but periodic recalibration may be necessary depending on the application and environmental factors to maintain measurement accuracy.

Are there any software tools available for OLS700D3LSH integration and data analysis?

- Yes, the manufacturer provides software tools and development kits for OLS700D3LSH to facilitate integration, configuration, and advanced data analysis within technical solutions.